ABOUT COMPANY

DTD FUTURE s.r.o. company was established in 2004 with the aim to offer to it´s clients complex solution of their requierements in the area of supplies of the components for technological equipments.

The key field of the activities of the company are Power engineering, Chemistry, Transport technology and Constructions.

Thanks to many years´experience and references from great customer´s companies have been realized supplies and services on the basis of long-term general contracts. In the area of service activities is the company able to react quickly and flexibly to requirements of the customers not only in the area of material supplies but also by working out various technical tailor – made supplies solving requierements of the clients completely.

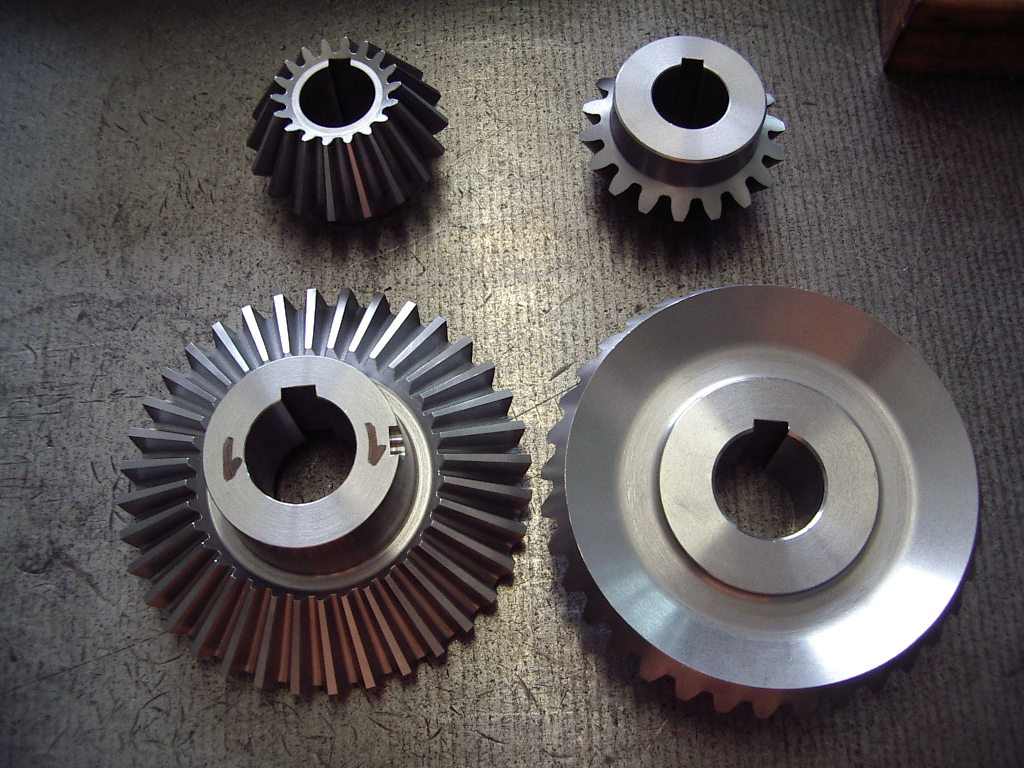

DTD FUTURE s.r.o. company in an effort to offer to it´s clients not only supplies and montage of new components but also with the emphasis on economy of operation, lifetime and returnability invested assets, performs renovations of the components by method of hot spraying including high velocity oxygen fuel metal – ceramic and ceramic materials.

These technologies are in the long – term used by renovations of the components of the trams and trolley – buses. Another very important area is performance of renovations of the components of hydraulical and steam systems (shafts´pump, shafts, regulations of turbines…).

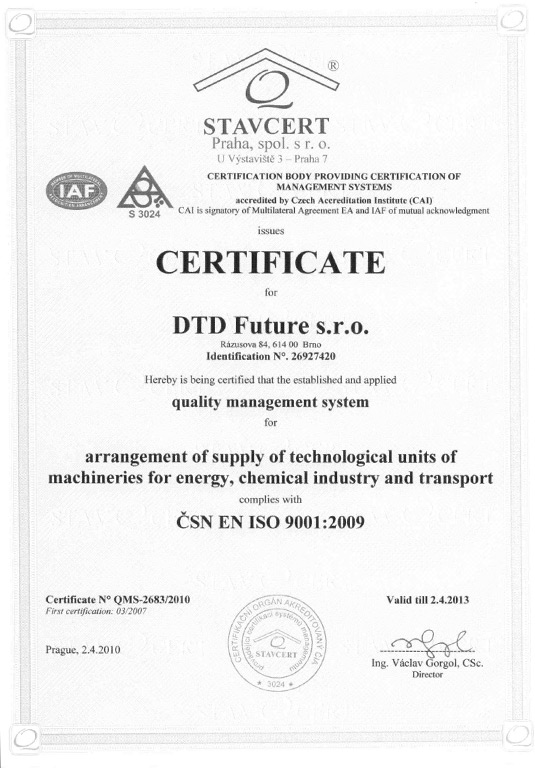

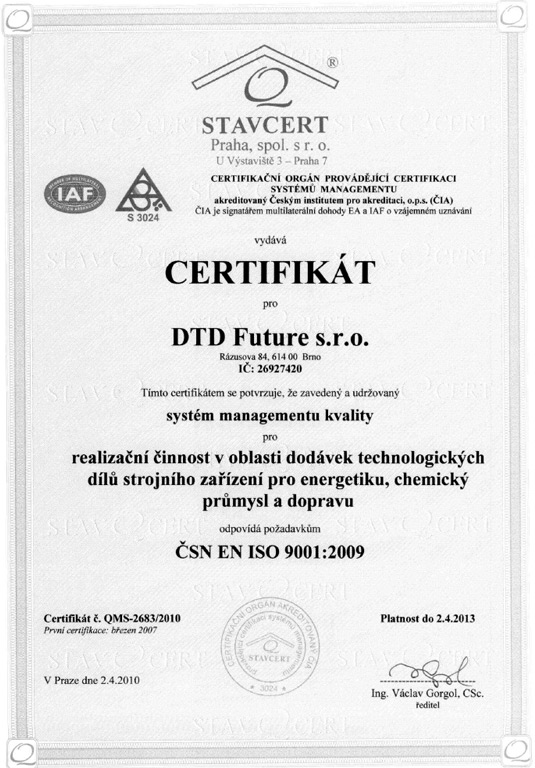

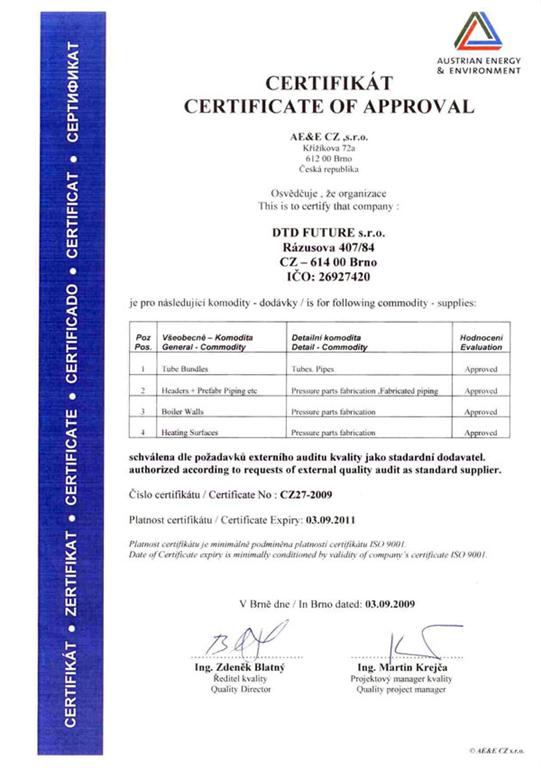

Not only due to long – term high quality of supplies and services and high number of references in above mentioned fields but also due to laying down clearly defined internal processes, the company was certifiend in the year 2007 according to ISO 9001.2001 international standards. In the year 2011 was the certification renewed. DTD FUTURE s.r.o. company is the holder of the quality certificate according to the ISO 9001.2009 standards.

QUALITY CONTROL IN OUR COMPANY

QUALITY POLICY OF FUTURE DTD s.r.o.

Our goal is to integrate quality into all aspects of our business.

Responsibility for product quality can not be delegated.

Each employee is responsible for continuous improvement activities carried out.

Leaders of all levels of management are responsible for ensuring that it creates for them the right conditions. Emphasis is also placed on product safety, health and safety at work and environmental protection.

Quality is defined as meeting the requirements and expectations in terms of quality and technical service levels.

Measure of quality for us is customer satisfaction.